45C 42Y / 45C 96Y

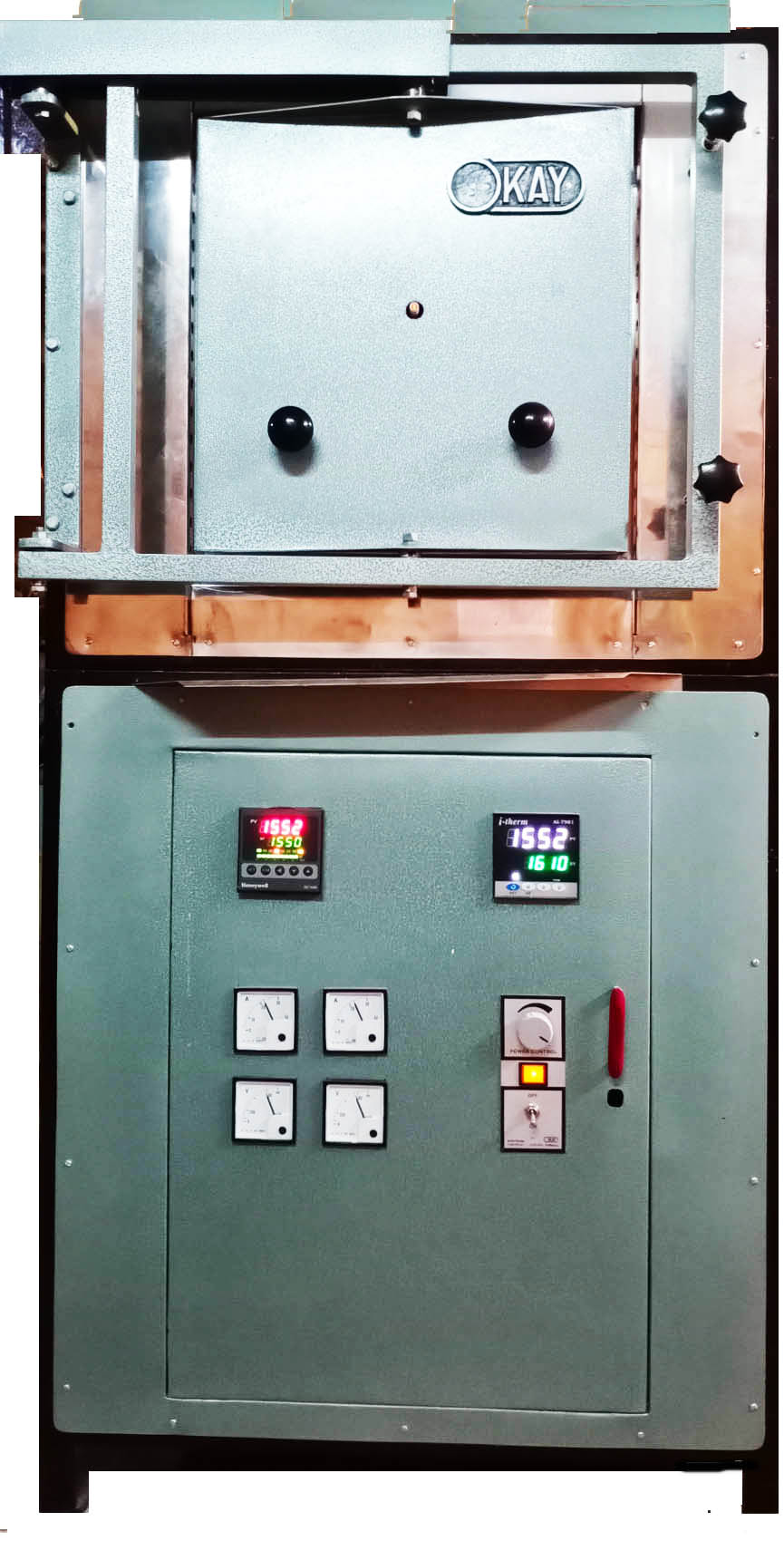

Laboratory Furnace upto 1450°C with Silicon Carbide Heating Element

GENERAL FEATURES & DESCRIPTION :

- Silicon Carbide Heating Elements in matched sets ensure better temperature uniformity and longer element life. Elements mounted Horizontally or Vertically.

- Hot-face Refractory High Alumina insulation backed by low heat capacity refractory and Fibrous insulations of different grades

- Dual Shell with Fan cooling to ensure low Skin temperature.

- Insert type Swing aside Parallel – moving Door ( Chain guided) with Peep Hole facing away from the Operator in any position. Fiber wool sealing in the Door for least Heat leakage

- Thyristorised Circuitry with adjustable Current limit and Soft-Start features for maximum protection to Heating Elements and for simple control of heat-up rate.

- Micro-processor based Digital PID Temperature Controller / Programmer with Pt/Rh Thermocouple (Type ‘R’) in pure Alumina Sheath.

- Digital Over-Temperature Protector with ensure overall safety.

- Exhaust air outlet at Roof of the Furnace

- PC Interface for On –line Date Acquisition / Storage Graph / Table also available (Optional)

PERFORMANCE :

- Temperature Control Accuracy within ± 1°C of set point.

- Temperature uniformity within ± 5°C near T'max with soaking.

- Carefully Engineered for rugged use and easy maintenance.

- Easy Installation and Hassle Free Operation

APPLICATIONS :

- Trial firing and P.L.C.A.R. Testing

- Industrial R & D work

- Thermal testing in Quality Control Laboratories

- Sintering and Processing in Powder Metallurgy

- Precision Batch firing of Ceramic Products

- Trial firing and P.L.C.A.R. Testing

- Industrial R & D work

- Thermal testing in Quality Control Laboratories

- Sintering and Processing in Powder Metallurgy

- Precision Batch firing of Ceramic Products

CONSTRUSTION :

- Welded angle-iron frame for Floor model construction in two sections with hammertone painted sheet-metal paneling,M. S. welded sheet-metal for TableModel box type fabrication in a composite assembly of two sections with hammer-tone paint Top section comprises the Heating Cavity assembly for Floor Model and Heating Cavity is located on the left of the assembly for Table Model.

- Base frame houses with Electrical gearing (Analog Voltmeter, Ammeter Switches etc.) thereby needing lesser floor area for Floor Model and for Table Model, Control Panel with electrical gearing (Analog Voltmeter, Ammeter Switches etc.) is positioned on the right.

- Heat-affectable metallic parts in the vicinity of Door opening are of heat-resisting Stainless-Steel fabrication.

CONCISE SPECIFICATIONS :

T' Max |

Model |

Cavity

|

Size

|

(mm)

|

Hours to

|

K W |

|

1450°C |

45C 6Y* | 150 | 150 | 250 | 3.0 |

4.0 |

| 45C 12Y* | 200 | 200 | 300 | 3.0 |

6.0 |

|

| 45C 42Y | 300 | 300 | 450 | 3.5 | 12.0 | |

| 45C 96Y | 400 | 400 | 600 | 4.0 | 16.0 | |

| 45C 200Y | 420 | 400 | 1200 | 6.0 | 24.0 |

[‘*’ denotes Table models ]

45C 6Y / 45C 12Y